English

Magyar

English

HUNGARO COPTER

Weboldal alcíme

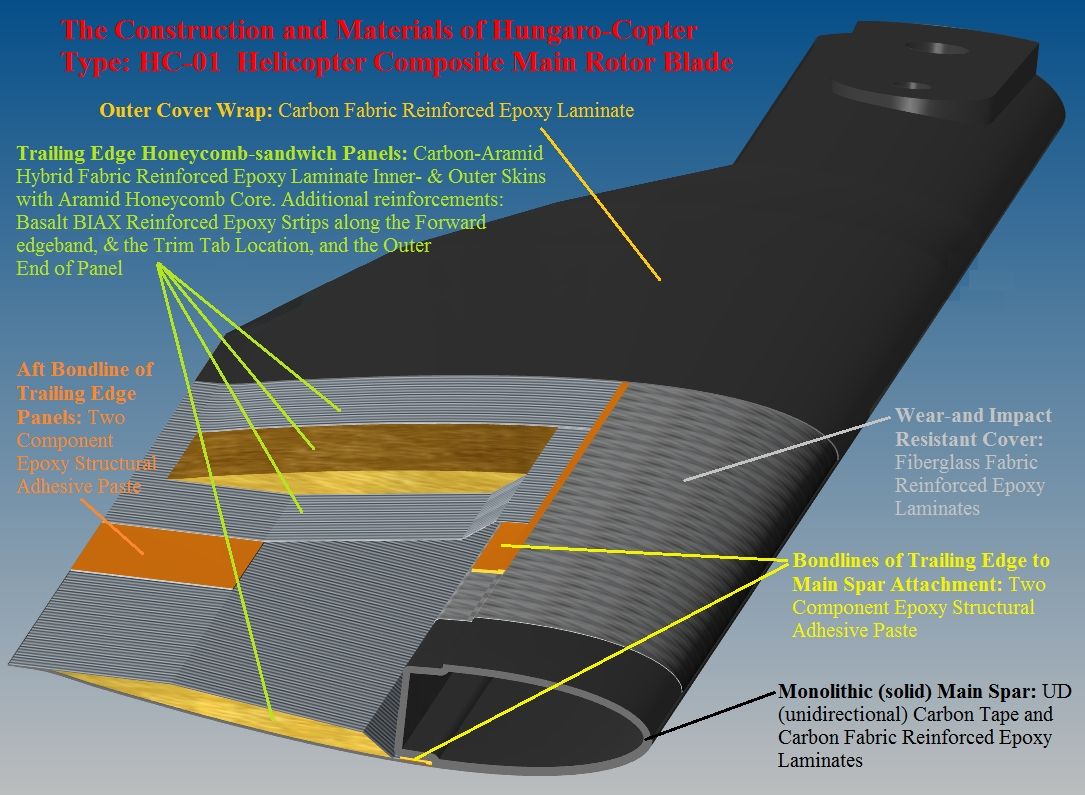

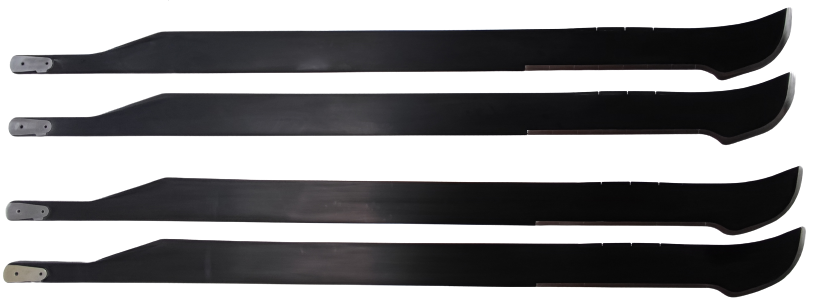

Composite rotor blade

The composite materials are the most suitable to meet the aerodynamics and mechanical requirements for example: low structural mass, but also durable rotor blades. In the aerospace industry , the most widely used matrix composites are the carbon fiber, fiberglass and carbon fiber epoxy resin reinforced with aramid-fiber, from the wide variety of these components, the materials have to be selected to manufacture of the rotor blades and to define the manufacturing processes.During the design of the blades, and by the requirements of strength-, stiffness-,the manufacturability is also has to be taken into account under the circumstances, therefore, a solid shaft, a closed box structure (monolithic) main spar has been developed, which is carboxylic aramid hybrid epoxy pepreg which is suitable recording the full load what is affecting to the rotor. whereas the order of layers of unidirectional (UD - Uni Directional) 0o orientation (the paddle same longitudinal axis direction) carbon reinforcing fiber webs, and +/- 45 ° fiber direction of carbon tissue has been designed, optimized in accordance with the loads occurring. The monocoque sandwich structure is reinforced with Nomex honeycomb.

Written by Imre Koncz aircraft-mechanical engineer.